Micro/nano Thermoelectric Technology

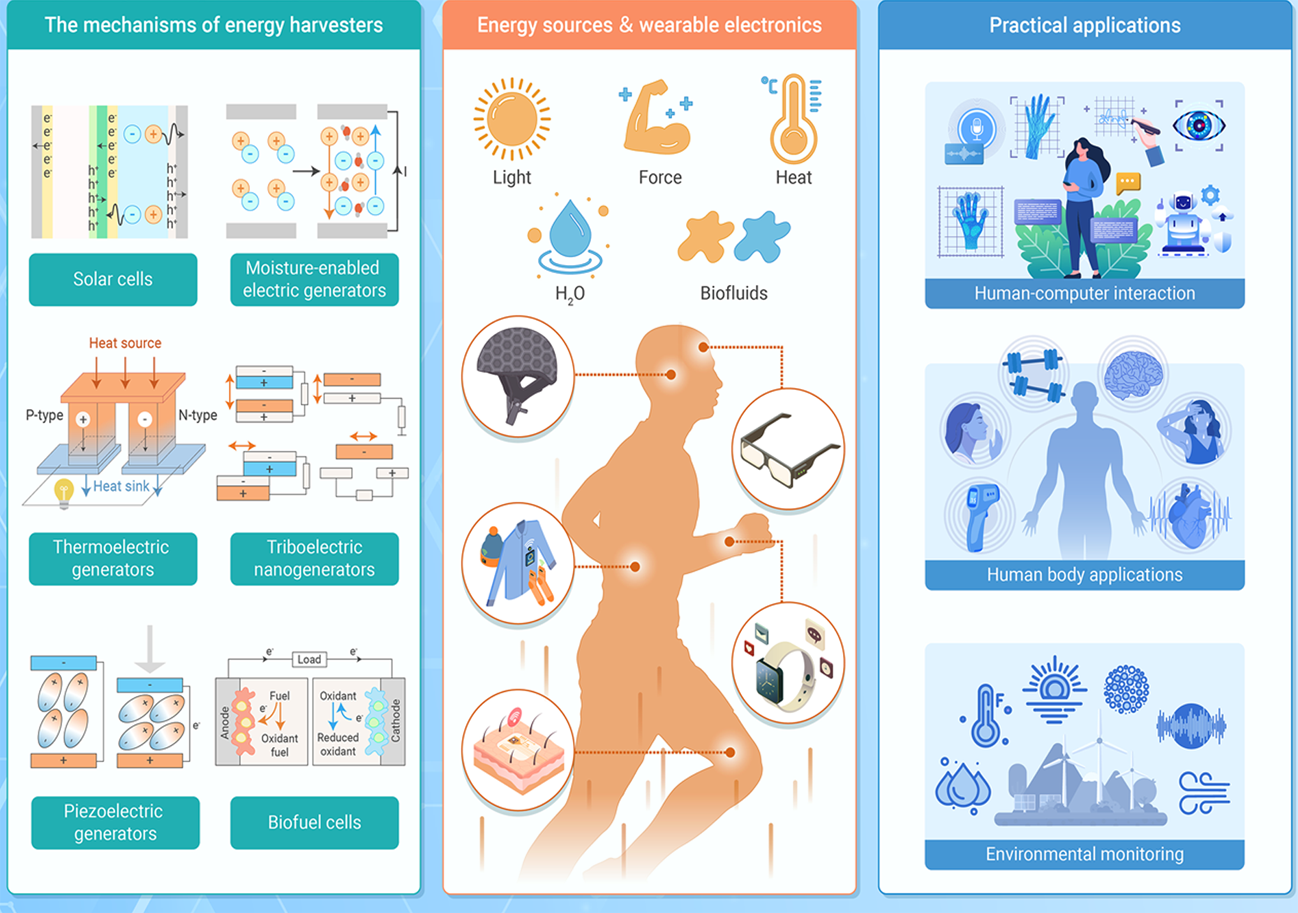

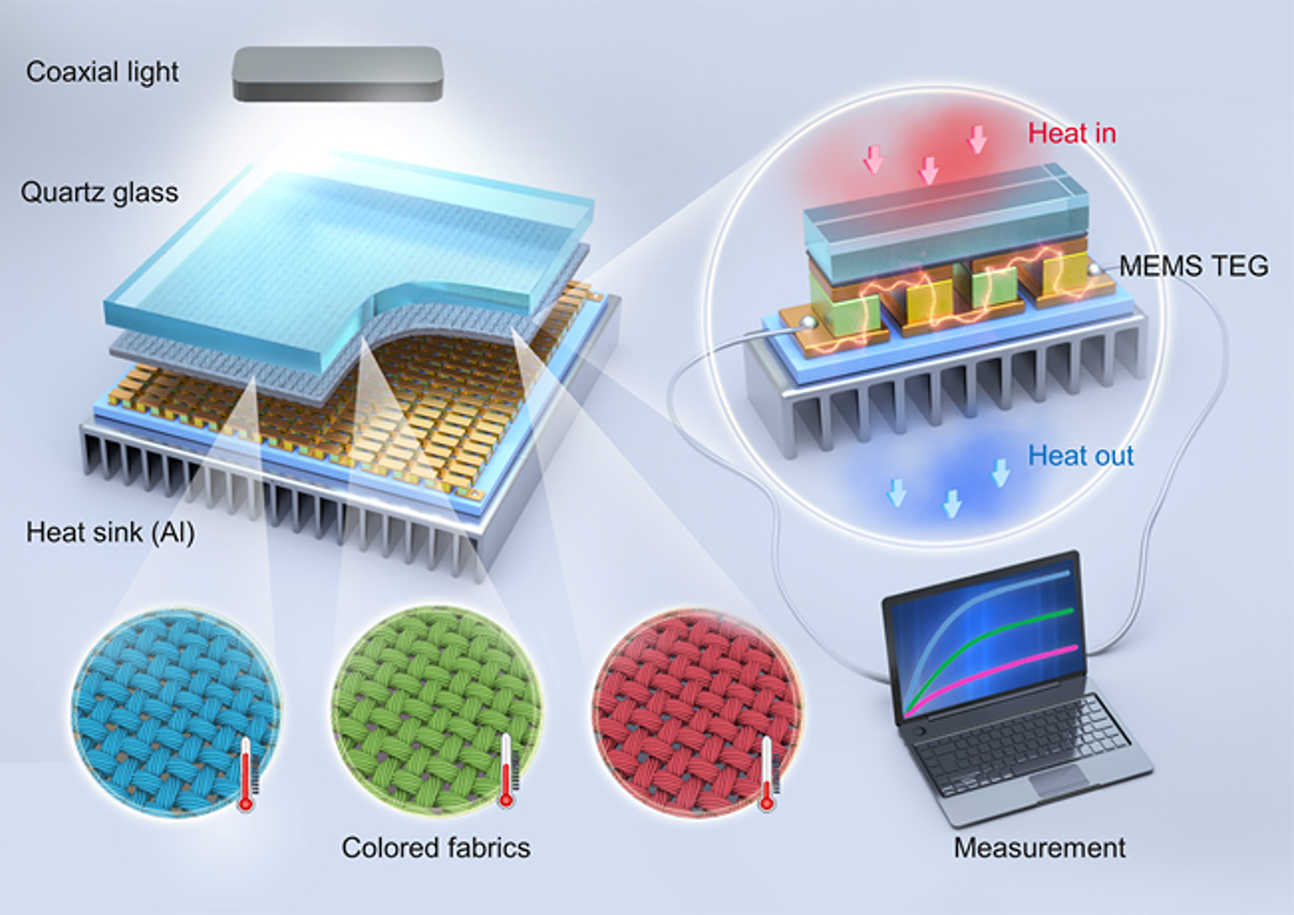

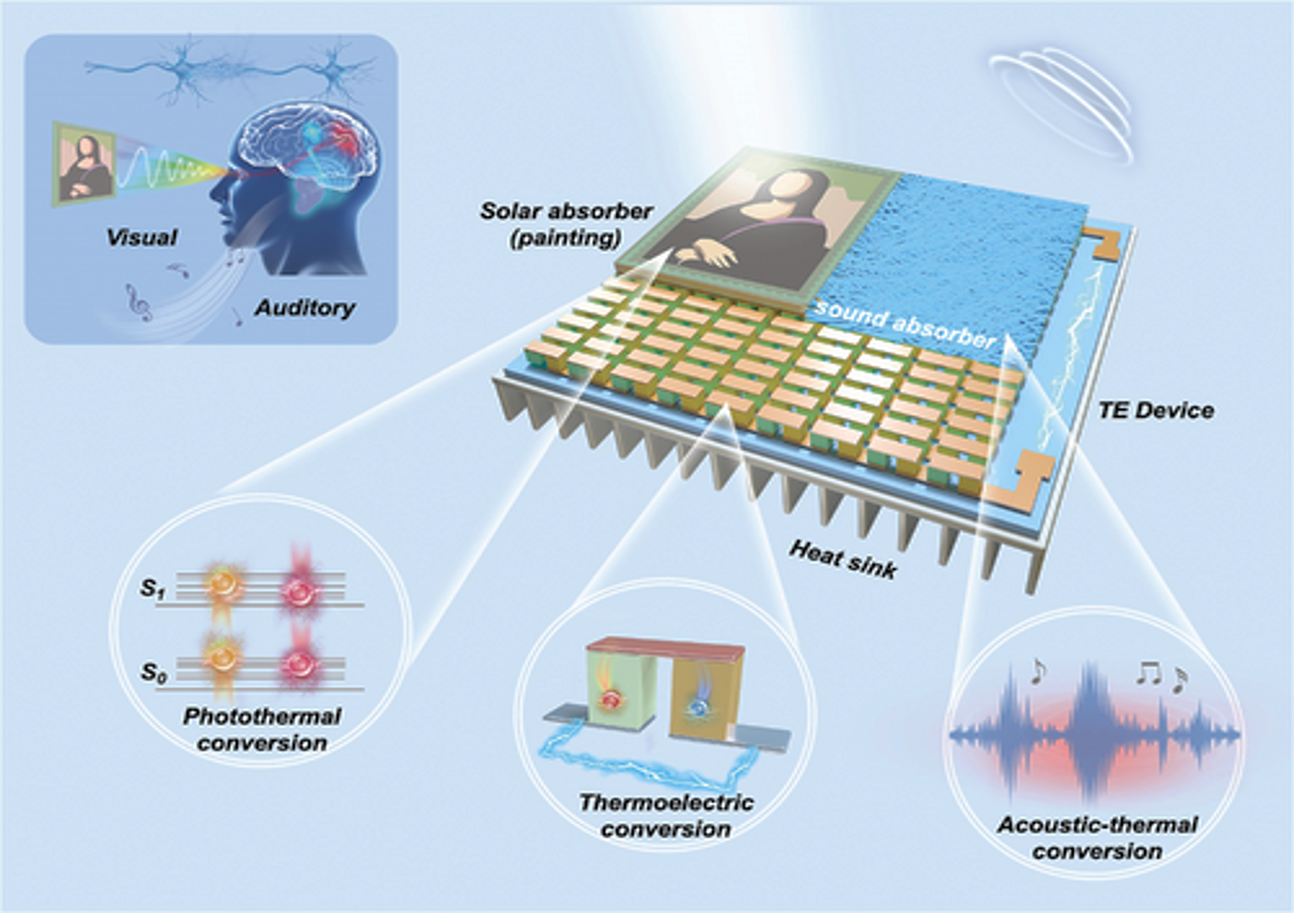

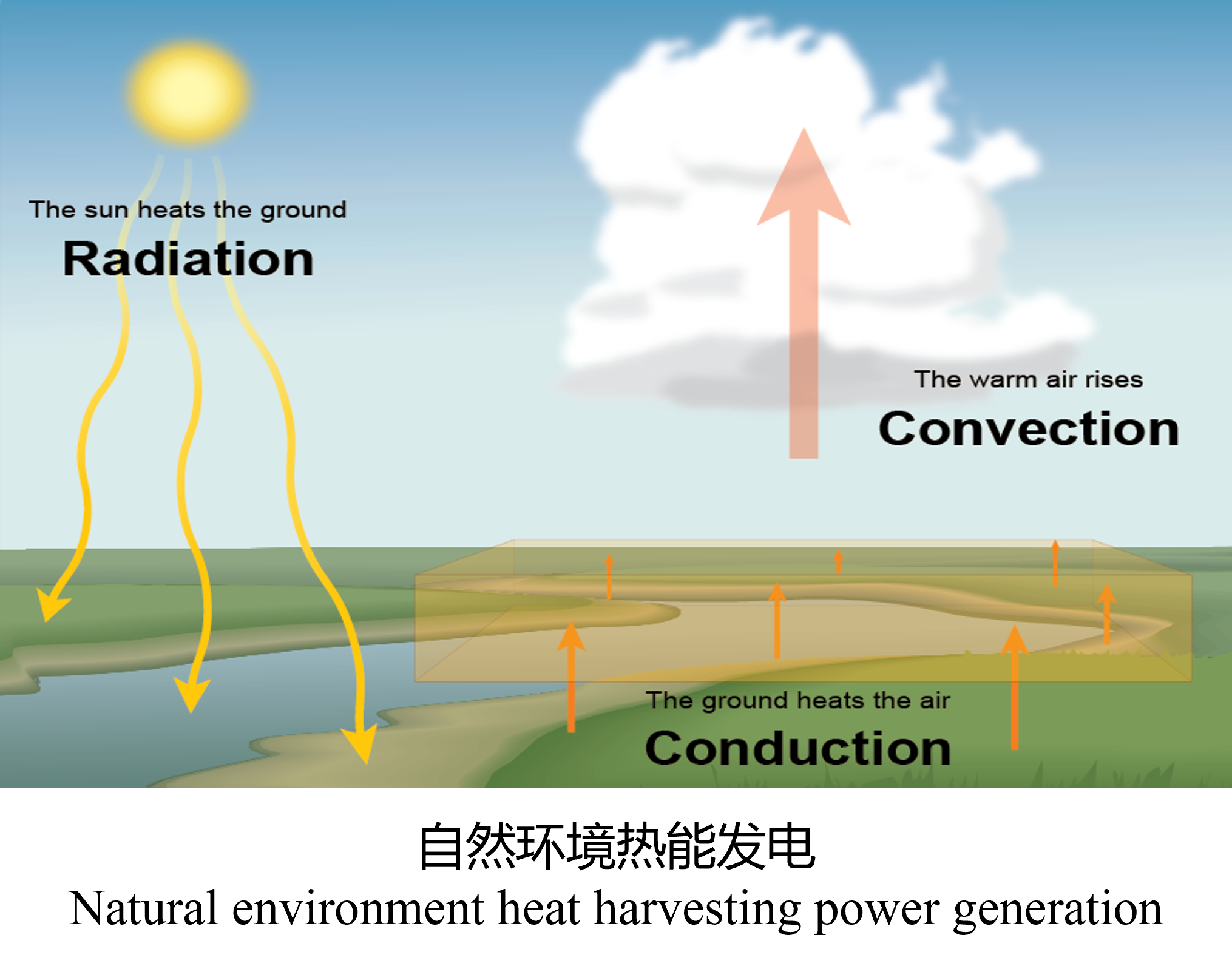

Microelectromechanical energy (MEME) thermoelectric chips achieve efficient energy conversion through innovative nanostructured materials and micro-nanoelectromechanical system design. They can provide sustainable green energy solutions for scenarios such as industrial waste heat power generation, environmental thermal energy utilization, IoT devices, wearable products, and industrial sensors.

Innovations in theory, equipment, material, fabrication and applications

Theoretical Innovation: Scale Effects of Heat

Nano-structuring: High-Efficiency Thermoelectric Materials

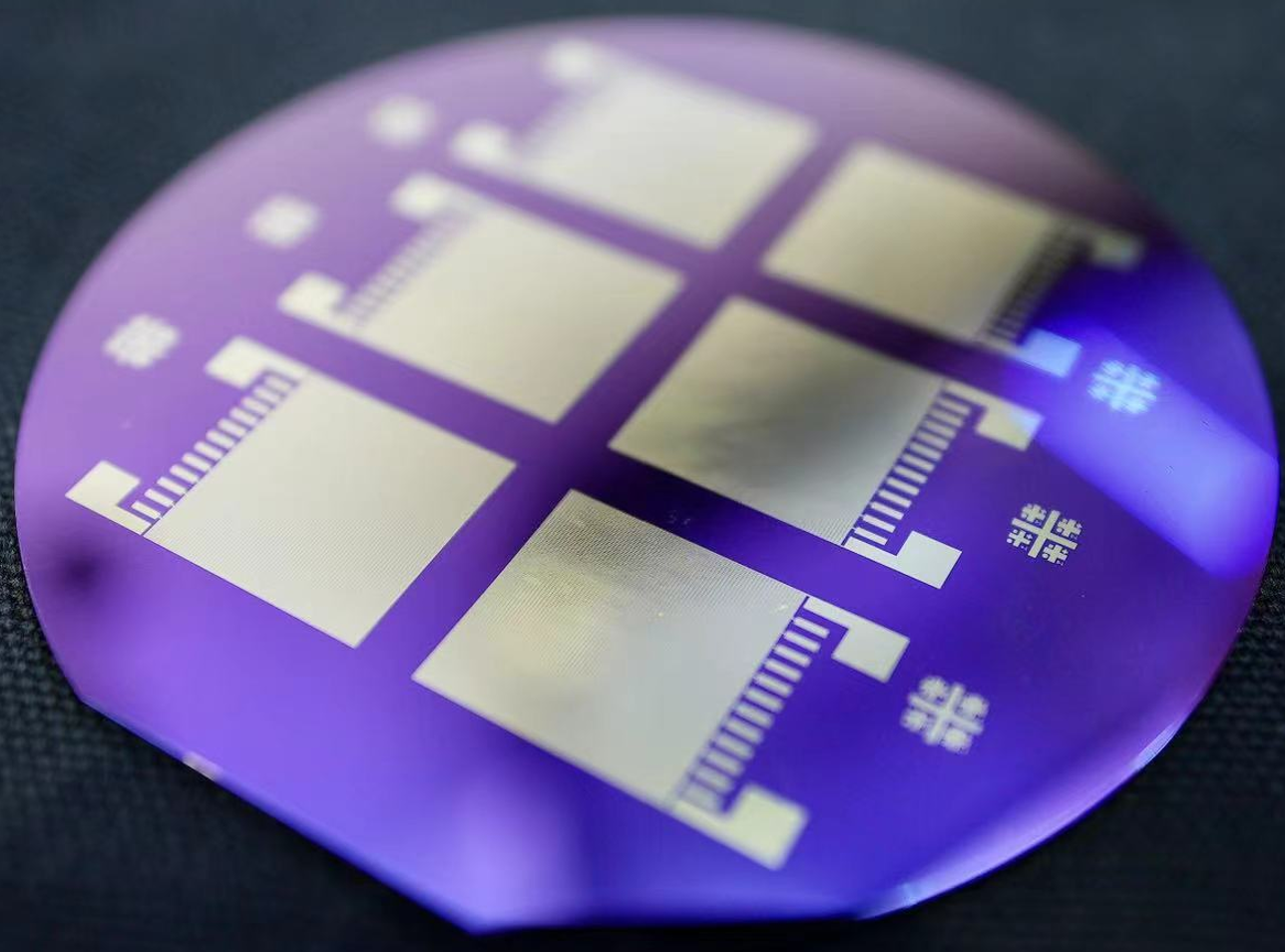

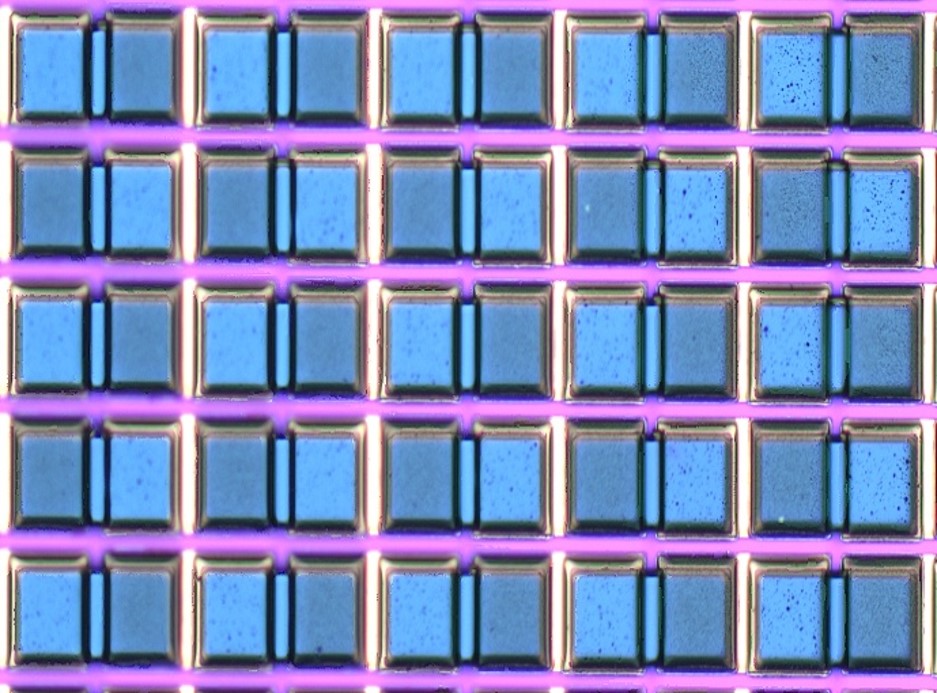

Micro/Nano-Fabrication: Large-Scale Production

Technological Breakthrough: Micro-Thermoelectric Power Generation

Precision Sensing: Next-Generation Sensors

Green Energy: The Micro-Nano Energy Revolution

The MEME Thermoelectric Chip combines thermoelectric effects with nanoscale engineering. Tens of thousands of thermoelectric pairs are integrated on a single chip, enabling efficient energy conversion even from tiny temperature differences.

MEME chips, featuring ultra-high sensitivity, low energy consumption, and seamless integrability, are emerging as a core technology for next-generation energy, sensing, and thermal management applications.

2024 R&D 100 Sustainability Innovator of the Year (Known as the "Oscars" of technological innovation)

Gold Medal, the 2024 Silicon Valley Innovation and Invention Festival, USA

Silver Medal, the 49th Salon International des Inventions de Genève, Switzerland

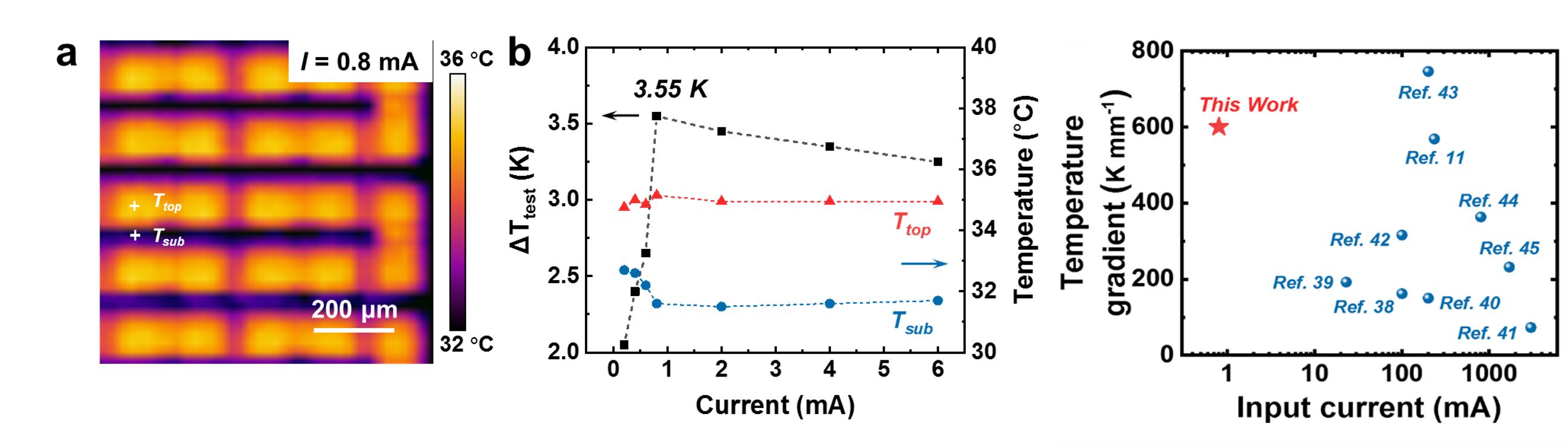

It can be bonded with CMOS chips to achieve 600K/mm chip-level cooling, effectively reducing the chip hotspot temperature.

Planar array high-precision temperature difference sensor: 0.001K sensitivity.

Temperature sensors used in high-end analytical and testing equipment

Identifying colors and materials

Quantitative measurement of images and sounds

Wearable sensors for humans and robots

High-efficiency small temperature difference power generation breaks the bottleneck of low-grade thermal energy utilization and realizes efficient conversion of thermal energy into green energy in all scenarios.

We look forward to collaborating with you to explore the infinite possibilities of thermoelectric conversion.

Please contact us via email, and we will reply as soon as possible.